Learn how to use rust inhibitor to prevent flash rust.

Learn how To Use Rust Inhibitor To Prevent Flash Rust

The blasting process, wet or dry, can create rust. Obviously, the introduction of water allows for a chemical reaction that creates rust. To combat that reaction from occurring, Rust Inhibitor is used with the water/abrasive mixture during Dustless Blasting and as a rinse with treated water afterwards to actually clean and remove grease and chlorides from the surface.

When dry blasting, there is no water to promote cleaning and the substrate will actually have embedded blasting particles left behind. This could create a future coating failure due to the contaminants not being properly washed away. To combat rust from forming when dry blasting, simply rinse the material with Rust Inhibitor treated water after blasting.

Rust Inhibitor is Non-hazardous, biodegradable and completely water soluble. This simple step is critical to effectively remove contaminants to prevent flash rust for up to 72 hours.

How to Use

-

Blast with Rust Inhibitor Treated Water

Add Rust Inhibitor to the blast water in a 1/100 ratio. -

Rinse with Rust Inhibitor Treated Water

-

Use a fertilizer sprayer that screws onto a water hose and measures out the selected amount of rust inhibitor per gallon.

-

Or, with a mobile unit, add the rust inhibitor into the water tank, and use your built-in water pump and a hose to rinse. *See other considerations below.

-

-

Remove Standing Water from the Metal

Use a leaf blower or oil free compressed air to quickly remove any standing water from the metal. -

Avoid Re-Contamination

Dirt, body oil and moisture all cause rust. Be sure to wear clean rubber gloves when handling the metal and keep away from causes of additional moisture like rain and morning dew if left out overnight.

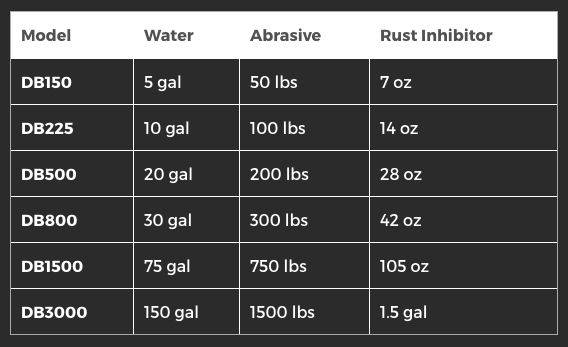

Refer to the chart below to find out how much rust inhibitor you should use.

Other considerations & tips

Well water

Using well water or hard water can affect how well the inhibitor works. You can combat this by adding a higher ratio of rust inhibitor.

Humidity in the environment

If you are in a high humidity area or have excess moisture in the air, a higher ratio of rust inhibitor will be required.

Frequent rinsing

If you're working on a larger project, you should rinse it with Rust Inhibitor as you go instead of waiting until the very end. The media sitting on the metal can leave spots and flash rust if left too long.