Pneumatic Deadman Repair Guide

Learn how to maintain your pneumatic deadman actuator by periodically replacing its wear parts.

What is a Deadman Actuator?

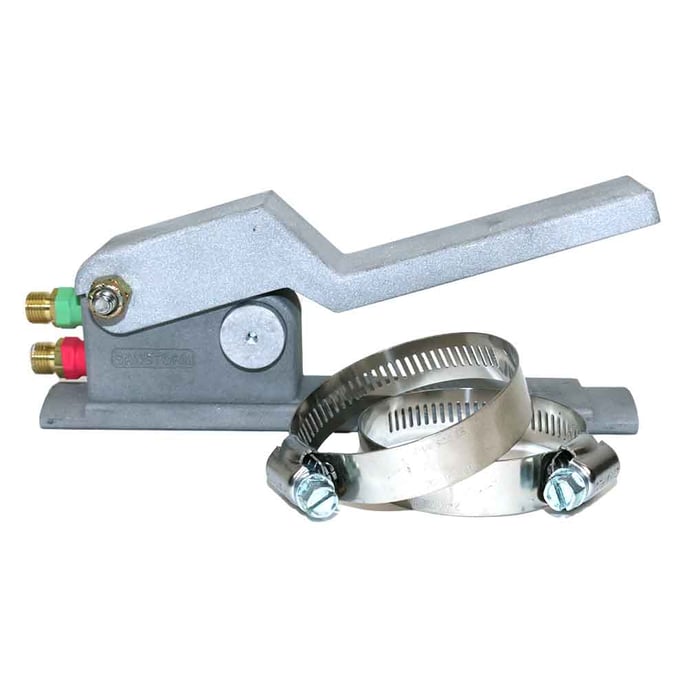

Also known as a Deadman control handle, the deadman actuator is an integral component of the sandblasting system. It operates as the on/off switch of your abrasive blasting system, providing you direct control over the flow of abrasive and air to the blast hose of a sandblasting machine. We offer both pneumatic and electric variations of this part.

Click here for instructions on repairing the electric red head deadman.

Why does this matter?

Why does this matter?

The Deadman actuator plays a critical role in maintaining safety on the jobsite. By providing operators with immediate control over the blasting operation, it can prevent accidents and injuries, making it a key element of any safety protocol for blasting operations.

In short, preventative maintenance of your Deadman actuator is not just a recommendation - it's a necessity. Thankfully, maintenance for this part is pretty simple and should only take a few minutes. You'll just need some basic tools and a part replacement kit from our store.

How to Repair your Pneumatic Deadman

Step by Step

- Start by pushing in the safety button to hold it in place. Loosen the bolt connected to it from the other side.

- Remove the bolt, safety button, and the large spring underneath the safety button. Inside our replacement part kit is a new large spring for replacement.

- Loosen the bolt on the top handle of the deadman controller and remove.

- Remove the top handle from the rest of the controller and inspect the small spring and seat disk. These are the two remaining wear parts to replace as needed.

- Reassembly is as simple as repeating the steps above in reverse.

IMPORTANT: After reassembly, ensure that the safety button on your deadman is functioning properly again before reconnecting it to your machine.