When to Replace Your Blast Hose

How to detect the signs of wear on your blast hose, and how to extend its life.

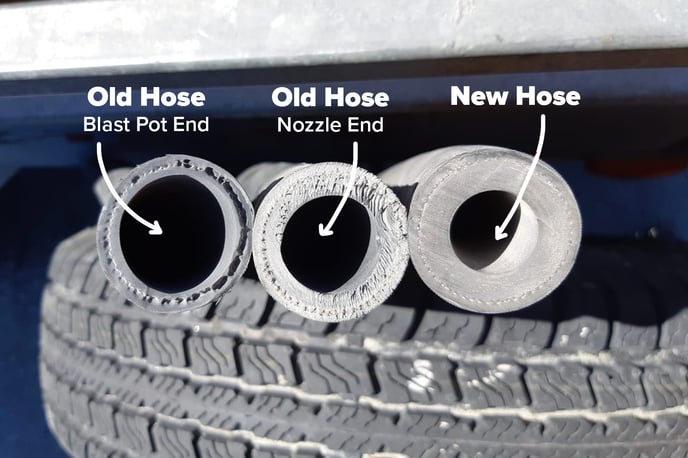

Blast Hose Wear

Just as your car’s tires wear away from contact with the road, the friction created by abrasive flowing through the hose wears away the rubber inside. Once the abrasive wears through the rubber inner tube, it makes short work of the hose’s reinforcing plies of braided strands and tough outer casing.

You can see the wear on this blast hose in the image below.

Another sign of wear is bubbling. If a bubble appears in your blast hose or pinch hose, it is in danger of bursting, and must be replaced immediately.

How to Check for Wear

Inspect the hose and its couplings for leaks every day. Check for soft spots by squeezing it about every six inches. Also, look for holes, cracks, and disintegration of the outer casing. If you discover several soft spots, holes or general deterioration, it's time to replace the hose.

How to Extend the Life of Your Blast Hose

Avoid Crimping

Avoid crimping or bending the blast hose tightly. Sharp turns will cause rapid wear. This is why hoses wear rapidly near the nozzle where the operator bends the hose over his shoulder to direct it at the surface being cleaned.

A blowout near the nozzle is especially dangerous to the operator. Stay safe by replacing your hose regularly and handling it hose with care.

If you need to blast in a tight space, consider adding a thin and flexible whip line extension.

Keep it Straight

Lay hoses in straight lines, keeping them away from vehicle traffic, chemicals, and sharp edges. Make bends gradual.

Support at Height

If the hoses run up scaffolding or structures, secure them every 20 feet and install safety cables to keep the weight of the hose from pulling apart couplings.

Store it Properly

After blasting, blow air through the hose to remove any remaining abrasive. Moisture and abrasive left in the hose overnight may collect in clumps, causing restrictions that increase wear. Gently coil the hose to prevent kinks and store it in a clean, dry area away from oil, chemicals, and paint. Do not hang blast hoses from racks for prolonged periods. This can cause kinks or worn spots on the outer casing.

Blast Hose Maintenance

Maintenance on the job just got easier! Stop fighting with dangerous knives and saws for cutting and repairing your blast hose. Quickly, easily, and safely cut your blast hose with this Supertool so you can safely reinstall your nozzle holder or couplings!

Purchasing Replacements

Even if you take all of these precautions, your blast hose will wear out eventually. When it does, you can easily order another in the Dustless Blasting Online Store.

"I replace my main blasting hose once a year. Think safety on your equipment and yourself. Don't think how much you can save now if you replace a part later when you have time. Make time and check your equipment often. Blast on brothers and be safe."

Jim D., Mobile Business Owner