Mobile Blasting Unit Best Practices

Basic tips for operation and preventive maintenance on your blaster to keep it running smoothly.

Air Compressor

The air that runs through your machine starts its journey at the air compressor.

Condensing fan

The condensing fan cools the hot air that comes out of the compressor. You don't really need the fan if you’re wet blasting, but it's very important if you’re dry blasting. You should also turn it on when using a paint spray gun with your compressor.

Because it never really hurts to have it on, we recommend just making it a habit of running the fan anytime the machine is being run.

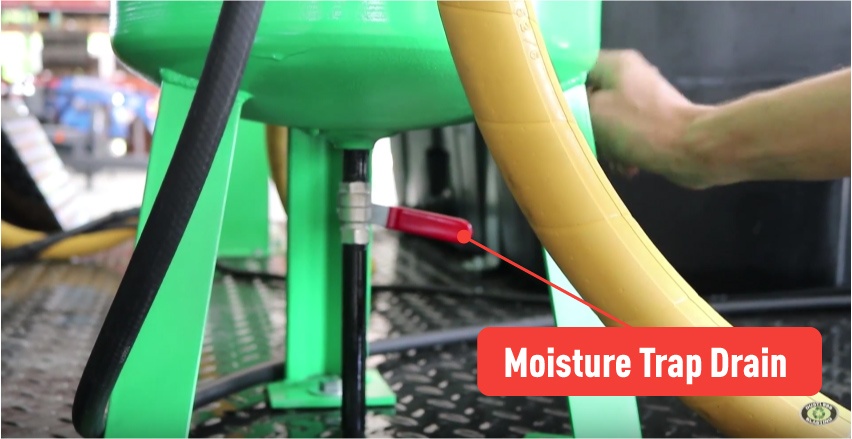

Moisture Trap

The moisture trap collects water from the air running through the system. Periodically drain it by opening the lever on the bottom.

Alternately, you can barely crack open the lever on the bottom so it can constantly drain slowly — this way you'll never forget! You won’t notice the minuscule difference in air pressure by cracking it open.

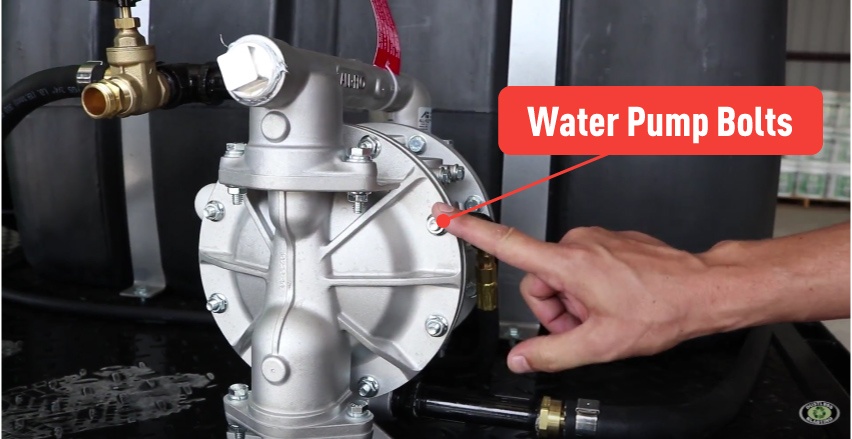

Water Pump

On the moisture trap, you will find a regulator for the water pump. We pre-set these regulators to about 80-90 PSI. You may use the regulator for your painting setup, but be sure to return it to 80-90 PSI when you're done.

On the moisture trap, you will find a regulator for the water pump. We pre-set these regulators to about 80-90 PSI. You may use the regulator for your painting setup, but be sure to return it to 80-90 PSI when you're done.

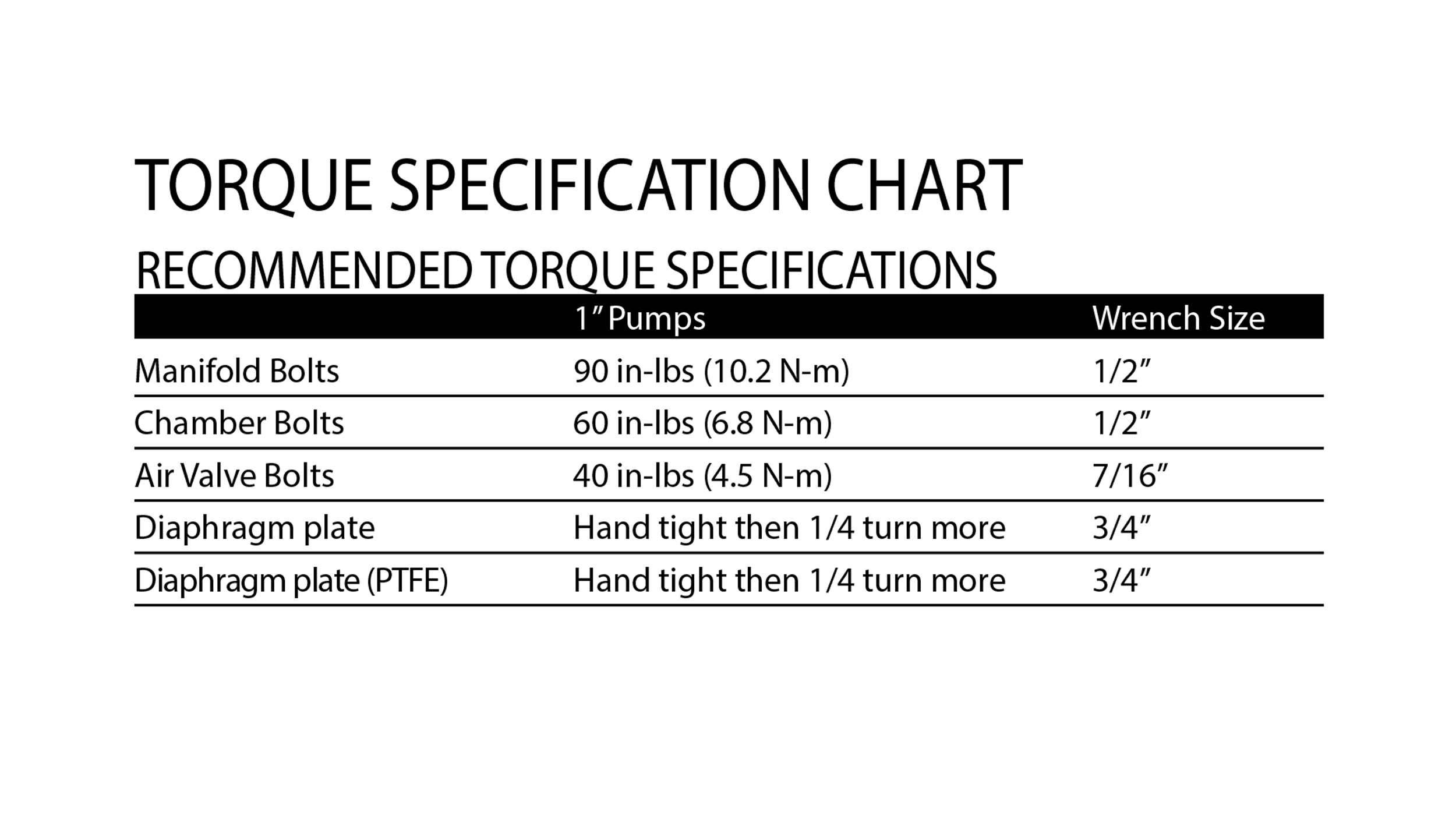

Every 10-20 hours of blasting, check the torque settings on the various water pump bolts. This will ensure you don't lose any air through the water pump, and get optimal performance.

Air Filter / Regulator

You will find the filter regulator on the left side of control box. Like the moisture trap, you should leave it cracked open so it can always drain. That way water will never get into your Parker valve.

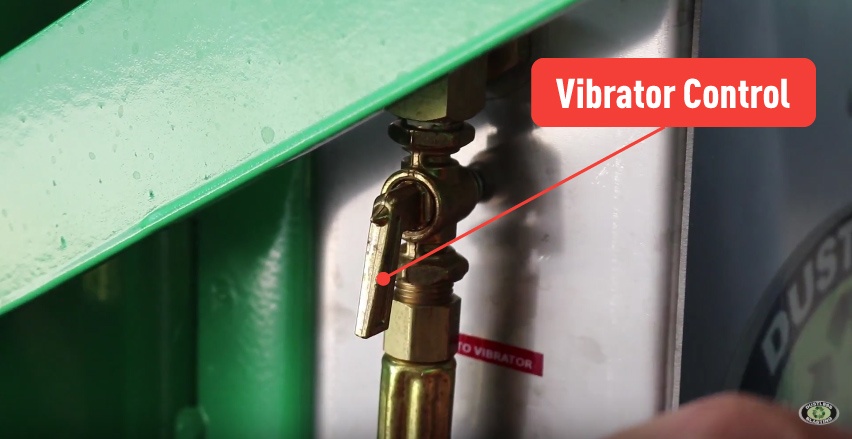

Vibrator Control Valve

Also on the left side of your control box, you'll find a small brass petcock valve which controls the vibrator speed.

Over time, you could experience abrasive buildup inside the pot which actually changes the harmonics of the pot. If you notice that the system is not feeding right anymore, you can adjust the valve (turn it off a bit). This slows the vibrator, allowing the pot to rattle more.

Pinch Hose

When you’re done blasting, push the bleeder button. This will relieve pressure on pinch hose, increasing its lifespan. Never do this under pressure!

The pinch hose is a wear part that will periodically need to be replaced.

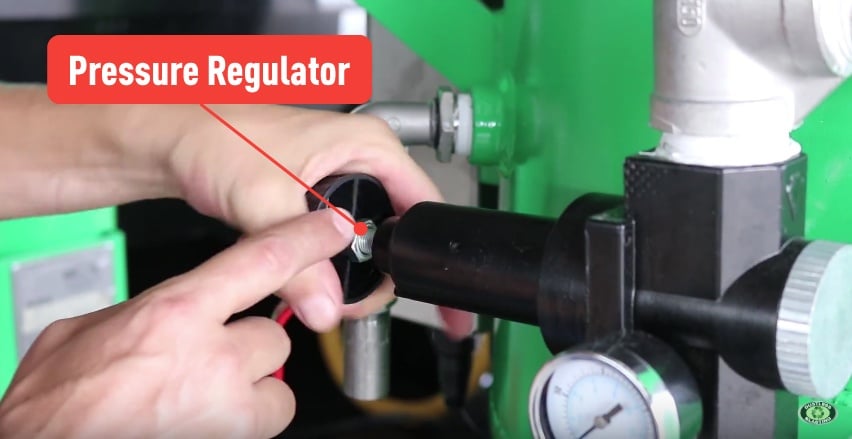

Pressure Regulator

You rarely have to adjust the pressure, because it is better to adjust with stand off distance. Occasionally you should lubricate the threads on this knob with something like lithium grease or Never-Seez.

Flushing the Pot

Regularly flushing the pot avoids buildup on inside walls, which could inhibit the system. Once a month or so, you should rinse the pot out.