Adjusting and Optimizing Media Flow

Use the abrasive control lever to adjust the media flow.

How the Abrasive Control Lever works

The abrasive control lever controls the rate of media pickup by raising and lowering the outlet pipe. The bigger the gap between the outlet pipe and the inlet jet, the more media and water gets sucked into the outgoing airstream.

The path of outgoing air through the machine

When the machine is under pressure, it will push this outlet pipe up as high as it will go, which would use WAY too much media. The knob on the abrasive control lever will restrict the height of the outlet pipe.

Optimizing Media Flow

- Load up your water and desired media, and adjust the pressure where you want it. If you're not sure how to do those things, read Choosing the Right Abrasive and Adjusting Blast Pressure.

- Start in the locked position, with the abrasive control lever all the way down.

- Increase flow in quarter-turn increments. Each quarter turn allows the outlet pipe to rise by about 1/16", which allows more media and water to get sucked into the outgoing airstream.

- Blast with each new setting.

- You may start to see some removal after 2 or 3 quarter turns.

- Once you see removal, keep increasing the media flow until the removal rate fails to increase.

- Once you’ve found the sweet spot, lock it in place with the locking nut.

- You can leave this setting alone until you change your pressure or start using different abrasive.

Your time is valuable and abrasive is cheap, so you don’t want to be too stingy with it. But after a certain point, the extra media flow is no longer beneficial, and finding that point is the key to optimizing your flow.

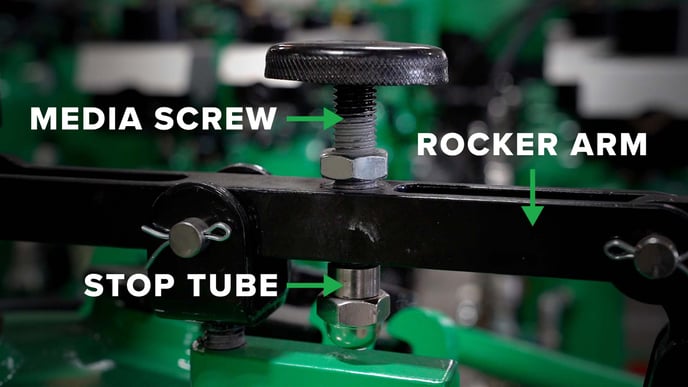

How the Stop Tube Works

This stop tube is a new safety feature designed to prevent any over adjustment of the media screw which could allow the rocker arm to slip out of the ring groove of the M17 head.

Didn't solve your problem? Contact tech support here or call 713-869-2227.