Choosing Blast Pressure and Blast Distance (VIDEO)

Learn what blast pressure or distance you should use for different projects.

Blast Pressure

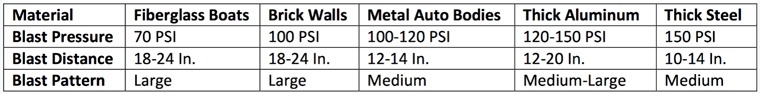

Different materials and coatings call for different pressures or blasting distances. Thick metal can handle a lot of pressure, while sheet metal could be dented by using too much pressure. Simple paint may come off nicely with the nozzle far away, while tough undercoating may come off better with the nozzle closer.

The distance you hold the blast nozzle from the material affects the harshness and speed of the blast and changes the "blast pattern" size. If you hold the nozzle too far away, the blast pattern will be big, but the coating will come off too slowly. If you hold the nozzle too close, the coating will come off quickly, but the blast pattern will be small. With a tiny blast pattern you'll have to move your arms a lot more to cover some area, which is inefficient. The best things is to find a nice balance between blast pattern size and removal speed.

Click here to learn how to adjust blast pressure on your machine.

Technique Matters

It's almost always better to hit the surface at a 45 degree angle, rather than straight on. This often removes coatings faster, and will creates less blowback towards you. Also, sweeping motions will achieve a more evenly blasted surface than random sporadic movements, and is more productive.

Common Guidelines

Marine

On thick steel like ship hulls, you can operate at about 150 PSI. Fiberglass requires a lower pressure — about 70 PSI — with a larger standoff distance.

Automotive

For most automotive uses, 120 PSI is ideal. Find a balance between blast pattern size, and speed.

For thick aluminum like a large trailer, you can blast at up to 150 PSI.

Graffiti Removal

For removing graffiti from a brick wall, use about 100 PSI so you don't etch the brick. The graffiti will still come off quickly at this low pressure.

Here is a chart of some suggested blast pressures:

Didn't solve your problem? Contact tech support here or call 713-869-2227.