DB500 Mobile XL - User Guide | Operation and Maintenance

Learn to operate your DB500 Mobile XL. Access manuals and user guides.

How to use the DB500 Mobile XL

User Manuals

DB500 Mobile XL User Manual

Rotair 185CFM Air Compressor Manual

Purchasing Parts

Shop Online for DB500 Parts

DB500 Exploded Diagram and Parts List

Warranty

Find warranty information for MMLJ and other equipment.

Tech Support

For Compressor Issues:

ELGi Compressors Tech Support

(704) 523-4123

Monday – Friday, 6:30 AM – 3:30 PM CT

For All Other Issues:

MMLJ Tech Support

(281) 869-3421

Monday – Friday, 8:30 AM – 5:00 PM CT

How to Use the DB500 Mobile XL

1. Hose Setup

Set up your blast hose and the deadman, which is the trigger. We go over this process in a separate video here.

2. Adding Water - part 1

Now it’s time to fill up your blast pot. You should always add the water first — it mixes better this way. You can use a water hose, but we’re going to assume you’re out on a job and you’ve already filled up your water storage tank, and we’re going to use our water pump to fill the blast pot.

First, we need to open the path from the water storage tank to the blast pot.

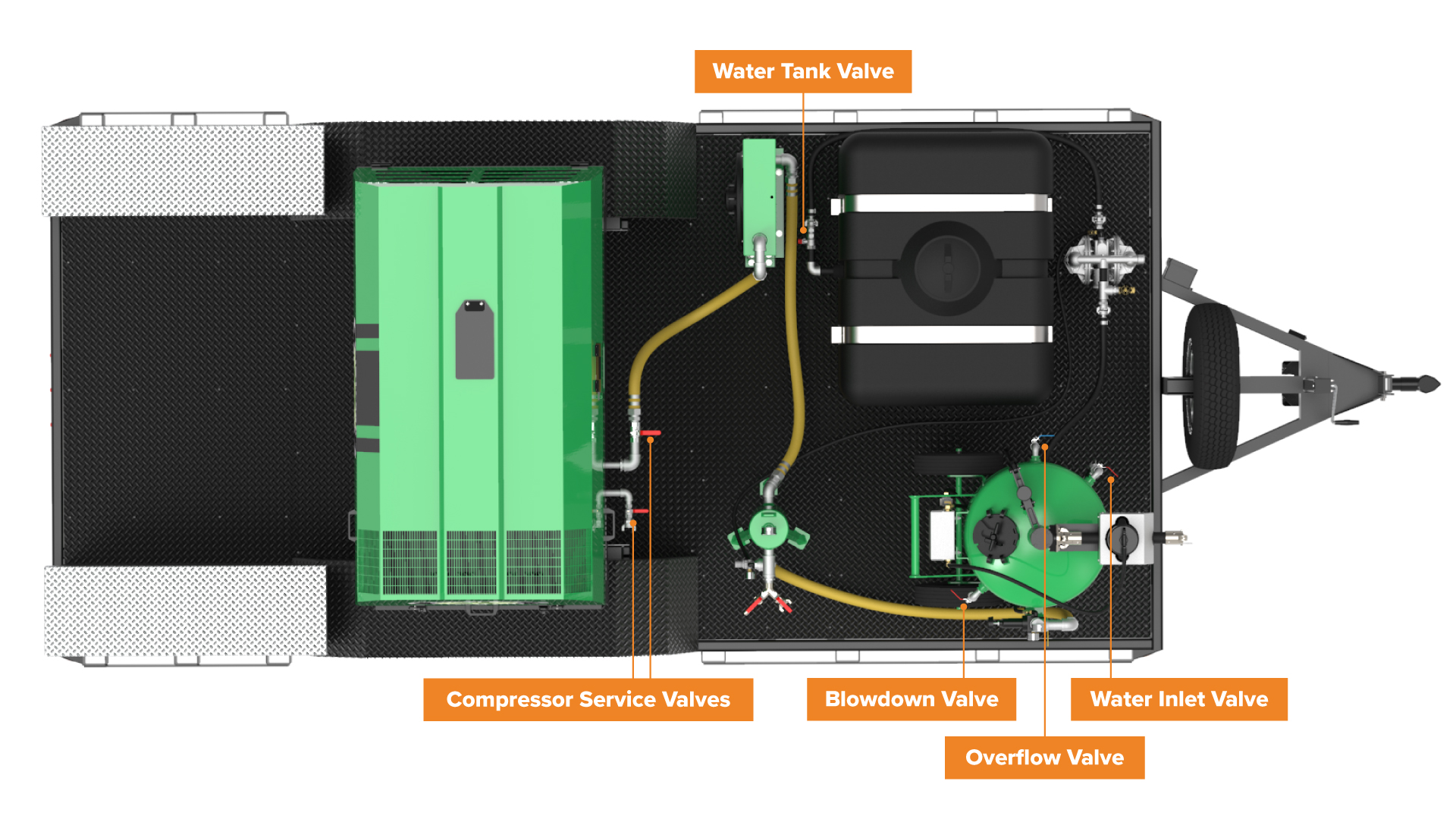

Make sure the water storage tank valve is open, and open the water inlet valve that goes from the water pump into the blast pot.

Open the blue overflow valve on the blast pot; this will let you know when the machine has reached the proper fill level.

The water pump is pneumatic, so to continue, we need to start the compressor.

3. Starting the Compressor

Make sure the compressor service valves are closed before starting.

Also make sure the air inlet valve is closed, and the blowdown valve is open. It might be helpful to remember that these two valves should always be in opposite positions.

Turn the compressor dial to the ON position. You’ll see the control panel light up, and once the Stop Engine light turns off you can press the START button. Release the START button as soon as the engine starts running, just like you would release the ignition in your car. The machine will idle and warm up for 15-30 seconds, at which point you’ll hear the engine change, and you’ll see the pressure gauge climb.

Now the compressor is ready for work, and you can open the compressor service valve. This will send air to parts of the blast pot plumbing and allow us to run the water pump.

4. Adding Water - part 2

On the Moisture Separator, you’ll find your auxiliary outlets, and below them will be a small valve. Open it to activate the water pump.

After only 30-40 seconds, water will start leaking through the overflow valve, letting you know the blast pot is full. Close the little valve to deactivate the pump, then close the overflow valve and the water inlet valve.

5. Adding Abrasive

Unlock the abrasive control lever so you can swivel the blast hose out of your way. Remove the fill cap.

The DB500 holds up to 20 gallons of water and 200lb of crushed glass abrasive, so for a full tank, dump in four 50lb bags of glass, using the funnel. Need help choosing the right abrasive for the job?

If you’re blasting metal and need to use the Rust Inhibitor, add 28oz into the blast pot now, unless you already added it to your water storage tank. Here's a video all about using Rust Inhibitor.

Replace the fill cap and make sure it’s locked.

6. Pressurizing the Machine

At this point, you’re ready to pressurize your blast pot, and start blasting.

Double check that the overflow and water inlet valves are closed. Close the blowdown valve, and finally open the air inlet valve.

Now you’re ready to blast! Of course you’ll want to fine-tune the abrasive control lever and adjust the blast pressure.

7. Blasting

Make sure you’re wearing proper protective equipment; gloves, eye and ear protection at the least. Hold on tight and depress the deadman toggle to blast.

8. Depressurizing and Shutting Down

Once you’re ready to refill, or shut down for the day, you’ll start by depressurizing your blast pot.

To do this you close the air inlet valve, and open the blowdown valve to release the air pressure. Now it’s safe to remove the fill cap if you need to refill.

If you’re ready to shut down, it’s important to close the compressor air outlet before turning it off, to prevent air from back-flowing into the compressor. Learn more about proper startup and shutdown procedures, to avoid damage to your compressor.

Turn the compressor dial to the OFF position and the machine will automatically cool down and turn itself off.

Reference Images

DB500 Mobile XL Trailer

DB500 Blast Pot